Ultrasonic Cutting of Cheddar Cheese Slices

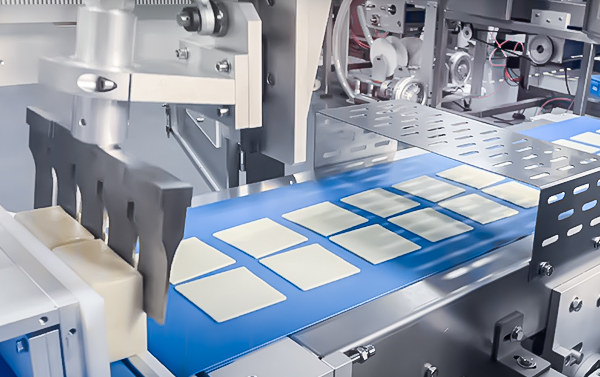

Ultrasonic cutting of cheddar cheese slices is an efficient and precise cutting method that uses the energy generated by ultrasonic vibration to achieve cheese cutting.

1. Advantages of ultrasonic cutting of cheddar cheese slices

Smooth and accurate incision: Ultrasonic cutting can ensure smooth and accurate incision.

No deformation: Since the friction generated during ultrasonic cutting is small, it can effectively avoid the deformation of cheese during cutting.

Low scrap rate: High-precision cutting reduces scrap rate and improves production efficiency.

Low maintenance cost: Ultrasonic cutting equipment has less wear on the tool, reducing maintenance costs.

Strong adaptability: Whether it is room temperature cheese or frozen cheese, ultrasonic cutting equipment can achieve good cutting effect.

2. Application of ultrasonic cutting equipment in cheese processing

Ultrasonic cutting equipment has broad application prospects in the cheese processing industry. It can not only be used to cut cheddar cheese slices, but also can be used for cutting other types of cheese and food raw materials. With the continuous improvement of the food industry’s requirements for processing accuracy and efficiency, ultrasonic cutting technology will gradually become one of the mainstream technologies in the field of food cutting.

Ultrasonic cutting of cheddar cheese slices is an efficient and precise cutting method with the advantages of smooth and accurate cuts, no deformation, low scrap rate and low maintenance cost. It has a wide range of application prospects in the cheese processing industry.

About Cheersonic

Cheersonic manufactures the leading portioning equipment for bakeries producing fresh and frozen desserts. Since 1998 bakers have used Cheersonic machines to cut, slice and portion cheesecake, pie, layer cake, loaves, butter, cheese, pizza, sandwichs, and more. Cheersonic offers ultrasonic cutting solutions that support start-up bakeries and high production commercial facilities alike. Small standalone machines can be used in manual baking facilities and large inline robotic solutions aid in high speed production.

Cheersonic offers many ultrasonic slicing models, both inline and offline applications, with production speeds of 80 to 1,500 cakes or pies per hour.

Cheersonic’ latest offline introductions include ultrasonic cutting with or without divider inserts between each slice. This improves the quality of the cut and makes for a much better product presentation for the customer. In addition, robotic arm improves the speed, efficiency, and accuracy of the cutting process, producing professional looking products every time.

Chinese Website: Cheersonic Provides Professional Ultrasonic Cutting Solutions