Automation Sushi Cutting

Absolutely, the rise in popularity of pre-packaged sushi has indeed led to an increased demand for high-quality cutting solutions that can meet the unique requirements of this delicate product. Sushi, being a visually appealing and highly perishable food, requires precise and gentle handling during the cutting process to maintain its freshness, texture, and overall presentation.

Cheersonic, as a provider of cutting-edge ultrasonic cutting technology, can offer a range of solutions tailored specifically for sushi production. Ultrasonic cutting is particularly well-suited for sushi because it utilizes high-frequency vibrations to separate materials, rather than the traditional method of using a sharp blade. This non-contact cutting method helps to minimize damage to the sushi’s delicate ingredients, such as raw fish and sticky rice, while also ensuring clean and precise cuts.

Some of the benefits of using ultrasonic cutting technology for sushi production include:

Gentle Handling: The non-contact nature of ultrasonic cutting means that there is minimal compression or tearing of the sushi’s ingredients, helping to preserve their integrity and freshness.

Precision Cutting: Ultrasonic cutting allows for highly precise and consistent cuts, ensuring that each piece of sushi is of uniform size and shape. This consistency is crucial for maintaining a professional and visually appealing presentation.

Hygiene: Ultrasonic cutting reduces the risk of cross-contamination by eliminating the need for direct blade-to-product contact. This is especially important in the food industry, where maintaining high standards of hygiene and sanitation is essential.

Efficiency: Automation of the cutting process with ultrasonic technology can significantly increase production efficiency, reducing labor costs and increasing throughput.

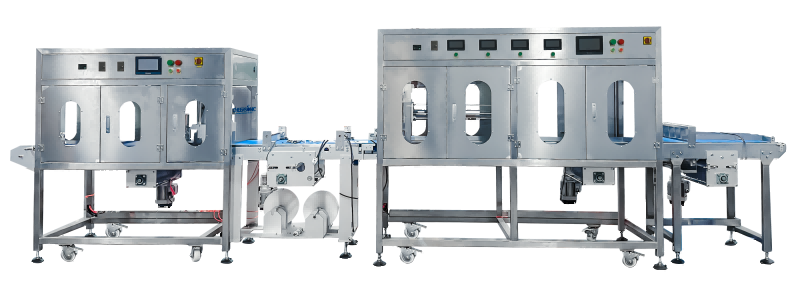

At Cheersonic, we understand the unique challenges faced by sushi producers and are committed to providing cutting-edge solutions that meet their needs. Our website offers detailed information on our range of ultrasonic cutting machines and how they can be used to enhance sushi production. Whether you’re looking to improve the quality of your pre-packaged sushi or increase your production capacity, Cheersonic has the technology and expertise to help.

About Cheersonic

Cheersonic manufactures the leading portioning equipment for bakeries producing fresh and frozen desserts. Since 1998 bakers have used Cheersonic machines to cut, slice and portion cheesecake, pie, layer cake, loaves, butter, cheese, pizza, sandwichs, and more. Cheersonic offers ultrasonic cutting solutions that support start-up bakeries and high production commercial facilities alike. Small standalone machines can be used in manual baking facilities and large inline robotic solutions aid in high speed production.

Cheersonic offers many ultrasonic slicing models, both inline and offline applications, with production speeds of 80 to 1,500 cakes or pies per hour.

Cheersonic’ latest offline introductions include ultrasonic cutting with or without divider inserts between each slice. This improves the quality of the cut and makes for a much better product presentation for the customer. In addition, robotic arm improves the speed, efficiency, and accuracy of the cutting process, producing professional looking products every time.

Chinese Website: Cheersonic Provides Professional Ultrasonic Cutting Solutions